As one of the best sellers in the Joskin muck spreader range, the NEW generation TORNADO muck spreader has been given several improvements as well as an upgraded design!

Since its creation in the late 90’s the Tornado muck spreader has continued to evolve and the basics on which it has built its reputation have continued to be improved: a narrow lowered body combined with larger diameter wheels allowing for easier traction and a reduced ground pressure thanks to an increased contact area regardless of the terrain.

A redesigned and optimised body

Compared to its predecessor, the body of the new generation Tornado is now more tapered and the side walls are smooth to make emptying and cleaning easier. The rear side has also been widened to increase the spreading regularity. The hydraulic pipes are now integrated into the upper body edge strip and therefore protected from any contact with the material. Finally, the mudguards have been redesigned with a 45degree inclination to avoid material heaps on the machine *Mudguards are an optional extra for NZ

Well-thought-out design

Whether it is the body or some of the components, such as the drawbar or beater frame, the Tornado is manufactured in high-tensile steel. This steel is characterised by its resistance and dynamic properties. It is thereby not necessary to add any side body reinforcements, which considerably reduces the machine’s empty weight. As for the beaters, they are designed to minimise the vibrations of the machine. For maximum protection and increased durability, the Tornado is also treated with 2K industrial paint.

VERTICAL BEATERS

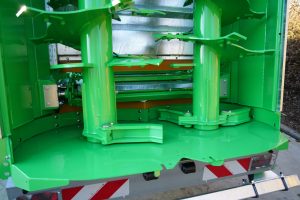

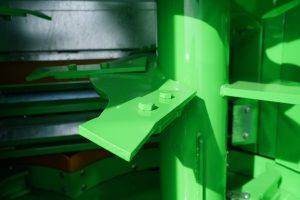

The model with vertical beaters is less expensive, low maintenance and the most common on the market. It is designed to spread heavier manure with straw over an area of 7 to 16m, depending on the material spread. Its design allows it to achieve very high spreading rates. To achieve them, the 2 slightly forward-sloping vertical beaters rotate at a speed utilizing the bolted teeth (80x12mm) at their base are two retractable blades (1,060mm) that project the manure and act as a smashing hammer. In the event of stones, the blades retract to absorb shocks and thus protect the entire drive system of the beaters (PTO shaft, gearboxes etc) the flow per hectare is easily adjusted by combining the speed of the tractor with that of the moving floor. The 1,010mm wide beaters of the Tornado are among the widest on the market and ensure a good crumbling of the material and precision spreading. A galvanised cord cutter can cut long fibres that may wrap around the beaters. The Vertical Tornado is available in 3 different body heights of 1.1m, 1.3m and 1.6m. It has been designed to best meet the loading height constraints of farmers.

FRONT BODY WALL

The front wall of the body is perforated for better visibility from the tractor cab, and a headboard prevents the material from falling onto the drawbar.

MOVING FLOOR

The moving floor is made out of steel tubes and two shipping chains (16mm marine chains with grade 80; the highest grade in traction chains currently available), the tension of which can be adjusted through 2 easily accessible mechanical side tensioners. The moving floor moves over a welded high tensile steel floor (4mm) and brings the manure to the spreading device which being wider than the body, allows the conveyed material to expand before ejection by the beaters. The direction of rotation can be reversed from the tractor via a double-acting hydraulic control valve.

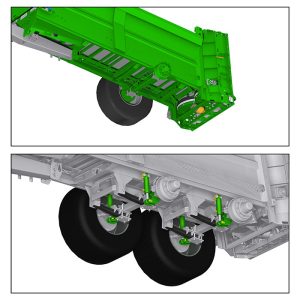

RUNNING GEAR

The single-axle Tornado has an oversized axle bolted under the body. it can be moved easily, which allows a perfect balance, with sufficient weight on the eyelet regardless of the chosen tyre configuration. The double-axle models are equipped as standard with a free-steering axle and a Hydro-Tandem hydraulic suspension, which ensures traction ease and optimal stability.

STANDARD EQUIPMENT

The Tornado is fitted as standard with a simplified closed-circuit hydraulic drawbar suspension and air brakes for unmatched driving comfort. A galvanised access ladder, a hydraulic skid, a wide-angle PTO shaft and retractable full LED lights also complete a rather extensive standard equipment list.

Words by: Paul Titus (Rural Contractor Magazine) // David Donnelly