Alpego is renowned for building professional power harrows to meet the demands of higher horsepower tractors and large-scale operations. Alpego is one of only a few manufacturers that use high-tensile steel in the construction of their machines. This is part of their philosophy of only using the best materials and components.

The high-tensile steel used by Alpego is sourced from SSAB which is one of the largest producers of high-tensile steel based in Sweden. They select their iron ore only from high-quality low-carbon iron-ore mines.

Other quality components used on Alpego power harrows include SKF and Timken taper roller bearings as well as Waltersheid drive shafts, only the best are used to provide high productivity and long life.

The most popular professional folding power harrow model in the Alpego range is the DK-TOP, which is available in working widths of 4m, 5m and 6m and are suited for tractors from 150HP up to a maximum input power rating of 350HP.

For contractors with larger tractors and who work large hectares looking for that extra robust heavy-duty power harrow for deep and extreme working conditions. Alpego offers the D-MAX models, which are available from 5m up to 8m working widths with a maximum input power rating of 500HP.

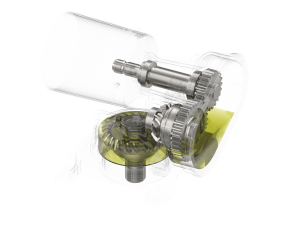

These high horsepower ratings are achievable by using special hardened helical-cut gears in the main gearboxes, which run smoother and quieter compared to straight-cut gears and last longer. This is the main reason why Alpego does not have problems with oil overheating, so it does not require oil coolers.

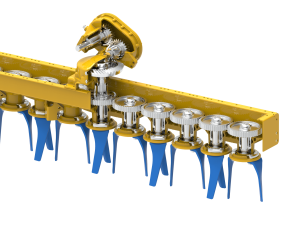

Alpego is reowned for their Twin-Force modular rotor system, which they ft on all their professional range of power harrows from the RM 170HP models up to the folding DmaX 500HP models. These use Timken conical roller bearings to allow for quick and easy serviceability of the rotors. The difference is should a bearing failure occur and damage the bearing housing, then you can easily replace the individual housing and rotor assembly as one module without having to replace the complete drive transmission bed.

A double labyrinth protection collar is machined into the bottom of each rotor to protect the seals, which makes it virtually impossible for material to damage the seals. Alpego provides a 2-year warranty on the rotor seals and the complete machine to back up this claim and their quality.

Auto-level is a further innovation on all Alpego power harrows. This feature ensures that the seedbed is perfectly level behind the machine by the rear-levelling bar that is attached to the roller, and not the machine by means of a parallelogram linkage. This means the levelling bar can work independently with the power harrow and tractor, so any irregular ground contours are backfilled with soil resulting in an even surface for planting. this is particularly appreciated when you lift the machine out of work on your headlands, as there is no ridge of soil left behind.